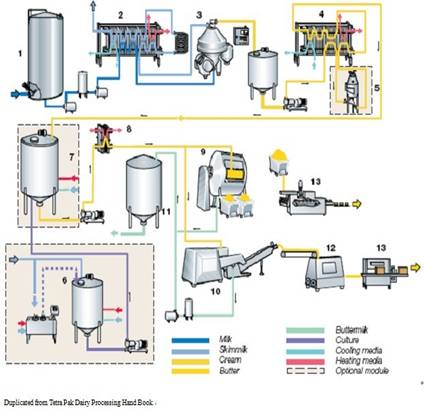

DESCRIPTION

Figure schematically shows both batch production in a

churn and continuous production in a butter making machine.

The cream can be supplied by a liquid milk dairy (surplus cream). From the

intermediate storage tank the cream continues to pasteurisation

at a temperature of 95C or

higher. The high temperature is needed to destroy enzymes and micro-organisms

that would impair the keeping quality of the butter. The heat treatment

releases strongly anti oxygenic sulphhydryl

compounds, which further reduce the risk of oxidation.

Vacuum deaeration can also be included in the line if

the cream has an undesirable flavour or aroma, e.g.

onion taste. Any flavouring will be bound in the fat

and transmitted to the butter unless removed. After this the cream is returned

to the pasteuriser for further treatment – heating,

holding and cooling – before proceeding to the ripening tank. In the ripening

tank, the cream is subjected to a temperature program which will give the fat

the required crystalline structure when it solidifies during cooling. The

program is selected to match factors such as the composition of the butter fat,

expressed for example in terms of iodine value, which is a measure of the

unsaturated fat content. The treatment can also be modified to produce butter

with good consistency despite a low iodine value, e.g. when the unsaturated

proportion of the fat is low. Ripening usually takes 12 – 15 hours. Where

possible, the acid producing bacteria culture is added before the temperature

treatment. The quantity of culture added depends on the treatment program

selected with reference to the iodine value.

From the ripening tank the cream is pumped to the continuous butter-maker or

the churn. In the churning process the cream is agitated violently to break

down the fat globules, causing the fat to coalesce into butter grains. The

cream is split into two fractions: butter grains and buttermilk. In traditional

churning the machine is stopped when the grains have reached a certain size,

and then the buttermilk is drained off. Buttermilk drainage is continuous in

continuous butter making machines. After drainage the butter is worked to a

continuous fat phase containing a finely dispersed water phase. If the butter

is to be salted, salt is spread over the surface in batch production, or added

in slurry form during the working stage in continuous butter making. After

salting, the butter must be worked further to ensure uniform distribution of

the salt. The working of the butter also affects the characteristics by which

the product is judged – aroma, taste, keeping quality, appearance and colour. The finished butter is discharged into the

packaging unit and thence to cold storage.

General process steps in batch and continuous production

of butter

1.Milk reception 2.Preheating and pasteurisation of skimmilk 3.Fat separation 4.Cream pasteurization 5.Vacuum deaeration (when used) 6.Culture preparation (when used) 7.Cream

ripening and souring (when used) 8.Temperature treatment 9.Churning/working

(batch) 10.Churning/working (continuous) 11.Buttermilk collection 12.Butter

silo with screw conveyor 13.Packaging machines

BENEFIT

1.Opportunity to realize products with customized recipes.

2.Opportunity to produce more than one product

with the same processing line.

3.High quality of the final product keeping an elevated nutritional value.

4.Wide customization of the final product.

5.Maximum yield, minimum production waste.

6.Highest energy savings thanks to the most advanced technologies.

7.Complete line supervision system through monitoring of every process phase.

8.Recording, visualization and printing of all daily production data.

CONSTRUCTION FEATURES

Working capacity

from 1 tons/d up to 50 tons/d

Products - Sweet

butter

- Sour

butter

- Salted butter

- Package in bulk container, small box