DESCRIPTION

Lines and equipment especially designed for the production and aseptic filling

of soymilk according to the highest quality international standards. The

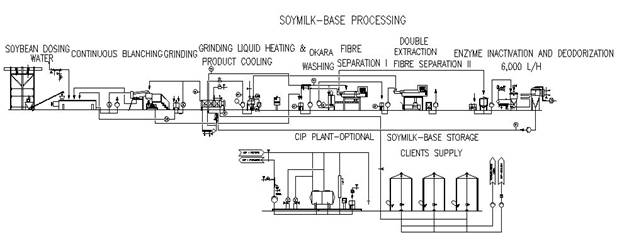

soymilk line production process is composed of the following phases: reception

of soy beans, dehulling, rehydration, grinding, solubilization, separation,

clarification, inhibition, standardization/formulation, homogenization, cooling

and storage, sterilization and aseptic filling. Soymilk can also be kept for

further processing in order to obtain, for example, flavoured soymilk,

soydrinks, beverages etc.

The separation phase allows to obtain a by product called “Okara” and generally

used as animal food.

BENEFIT

1.Opportunity to realize products with customized recipes.

2.Opportunity to produce more than one product

with the same processing line.

3.Very short holding times at pasteurizing temperature.

4.Accurate dosing of mixing and additional aromas.

5.High quality of the final product keeping an elevated nutritional value.

6.Wide customization of the final product.

7.Extended shelf life of the product.

8.Maximum yield, minimum production waste.

9.Highest energy savings thanks to the most advanced technologies.

10.Complete line supervision system through monitoring of every process phase.

11.Recording, visualization and printing of all daily production data.

12.Product higher quality with respect to traditional soy extracts.

13.Accurate

bean cleaning during soaking, removal of all colouring substances released by

soy during the rehydration phase.

14.Very fine grinding, dimensional reduction of particles.

15.Complete extraction of soluble components such as proteins, fats and

carbohydrates.

16.Full inactivation of the oxidization process due to lipoxygenase, no

unpleasant taste.

17.No product browning during the enzyme inactivation phase.

18.Non bean tast

CONSTRUCTION FEATURES

Working

capacity

from 1000 up to 40000 l/h

Products

- Soy milk

-

Flavoured soy milk

- Vitamin enriched soy milk

- Dietary fibre enriched soy milk

- Soy milk based drinks with juice fruit addition

- Soy yogurt

- Soy milk based puddings and desserts

- Bases for soy ice cream

- Soy milk powder